Litho-printing - Aluminium plate system.

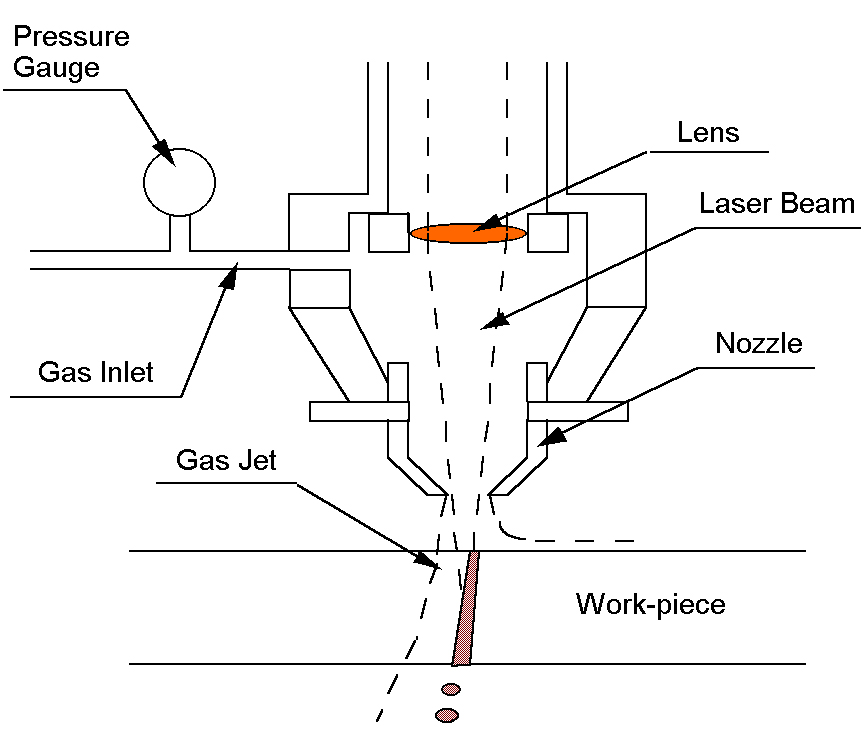

CTP - Computer plating system. Calibrated to printing. Image is burned into the Aluminium. And then the plate is used to print on the stock.

SRA2 up to B1.

Weights range from 70gsm to 450gsm.

Coated, Silk and Uncoated.

Uncoated tends to bleed very minimally, consider this in design. Coated is far sharper.

Litho machine prints 15000 sheets an hour.

Comparison between litho and digital.

Maximum you can print with digital is SRA3

Litho uses vegetable based inks, digital uses powder based inks.

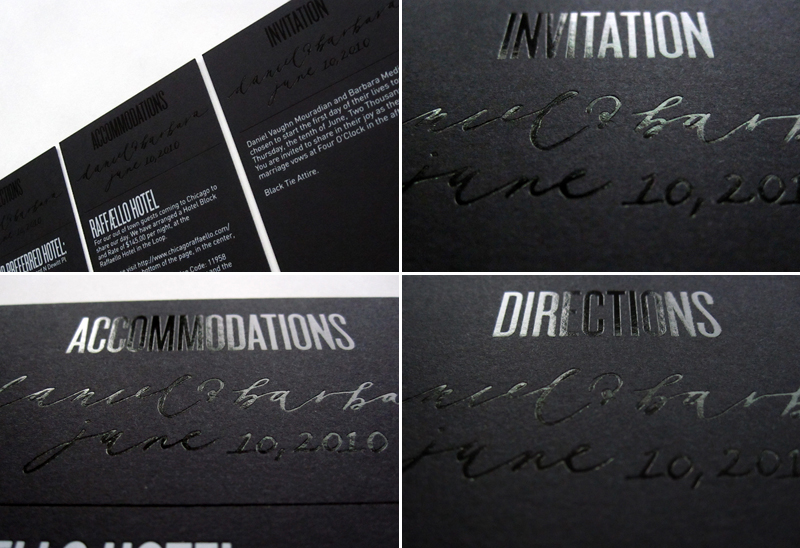

You can only use four colour process with digital whilst with litho you can use spot colours.

Digital pricing goes by click charge.

Litho by make ready charge, paper and plate charge.

Make ready is when the plate is put on the machine, a computer

Things Designers get Wrong:

1. Bleed - 3mm bleed and crop marks.

2. With booklets they must be sent as single pages.

3. If spot colours are in artwork but not needed don’t put them.

4. Transparency doesn’t work with spot colours, set as overprint.

5. Don’t fuck up scaling.

6. Keep at 300dpi.

To save money in pagination, work in 8ths, 16ths and 32s

Work and turn process is four plates.

Sometimes it is cheaper to print colour on white stock than use coloured stock.

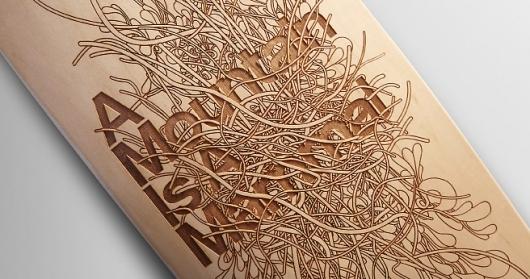

Binding and other finishing effects are done by out of house companies who they have developed relationships with.